|

TPX automatic machines for pressing and bending |

|

|

|

TPX 25 ADVANTAGES

- accurate automatic production of parts made of strip, wire or profile, which can be completed by assembling

- constant shape and dimensions of the products allow their use in follow-up operation without least problem

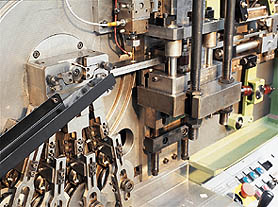

- the unit construction design using basic standard units with a wide range of accessories offers a rich choice of production possibilities including the input of different materials into the machine, their processing and assembling

- the course of operation may be easily followed up and the working parts may be adjusted operatively

- in case of a failure the defect spot is shown on the control panel and the machine is stopped automatically

- the tooling is adjusted with help of a hand wheel or of automatic stepping from the control panel or portable controller

- the infinitely variable speed allows to choose the most convenient outputof the machine

- mechanical or pneumatic ejection of the produced parts

- high reliability and long life of the machine

- the machines comply with the CE standards

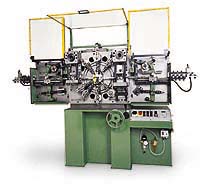

TPX 25

an automatic machine of well proved design for production of very accurate parts, with minimum requirements on operation and maintenance.

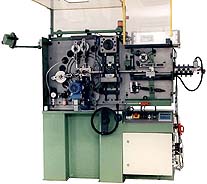

TPX 25 E

a TPX 25 version with electronic system surveying the operation of the machine including the tooling and protects the machine and the tools against damages in case of a failure. Fixed and free programmable entries into the system enable precise diagnostics of the technological process of the production. The free programmable entries enable to link up further operations.

Different modification and technology:

|

|

|

| TPX 25 with drawn-up covers |

TPX 25 with roller feeder |

TPX 25 |

|

|

|

| TPX 25 |

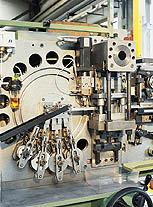

Technology TPX 25 |

Technology TPX 25 |

|

|

|

| Technology TPX 25 |

TPX 30 |

|

| Technical parameters: |

| |

TPX 25 + TPX 25 E |

TPX 30 |

| Feed step maximum length |

| - standard |

250 mm |

300 mm |

| - with roller feeder |

up to 10 000 mm |

| Processed strip width |

to 30 mm |

to 50 mm |

| Processed wire diameter |

to 3 mm |

to 4 mm |

| Automatic machine output - smooth regulation |

32 - 300 pcs/min |

25 - 250 pcs/min |

| Automatic machine maximum input |

2,2 kW |

8,2 kW |

| Pressure air (if required by technology) |

0,6 MPa |

| Maximum pressing power |

80 kN |

160 kN |

| Bending pressure |

20 kN |

40 kN |

| Electrical equipment |

3 x 400 V, 50 Hz |

| Machine main dimension (l x w x h) |

1500 x 840 x 1725 mm |

2710 x 980 x 2060 mm |

| Mass |

1020 kg |

2840 kg |

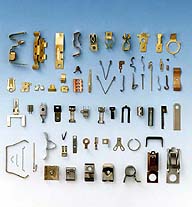

Products of automatic TPX:

| Products from wire |

Smaller products from strip |

Products from strip |

|

|

|

| Products from strip |

Mix products - strip and wire |

|

|

|

|

For the TPX automatics we recommend to order special accessories which are supplied upon separate order only:

- uncoiler QZ 80/1000

- roller feeder RP 8

- tapping unit ZJ 46-15

More detailed information are described in cataloques "Forming technology - Series TPX automatic pressing and bending machines".

| Contact: |

| Dipl. Ing. Hana Flígerová |

| THA machines sales manager |

| all the world |

| tel.: +420 491 549 340 |

| fax: +420 491 549 132 |

|

| e-mail:

hana.fligerova@kovopol.cz |

|